How does water cooling work?

Oreon has developed a water cooling technology that can be used in almost any greenhouse or indoor facility in collaboration with renowned installers.

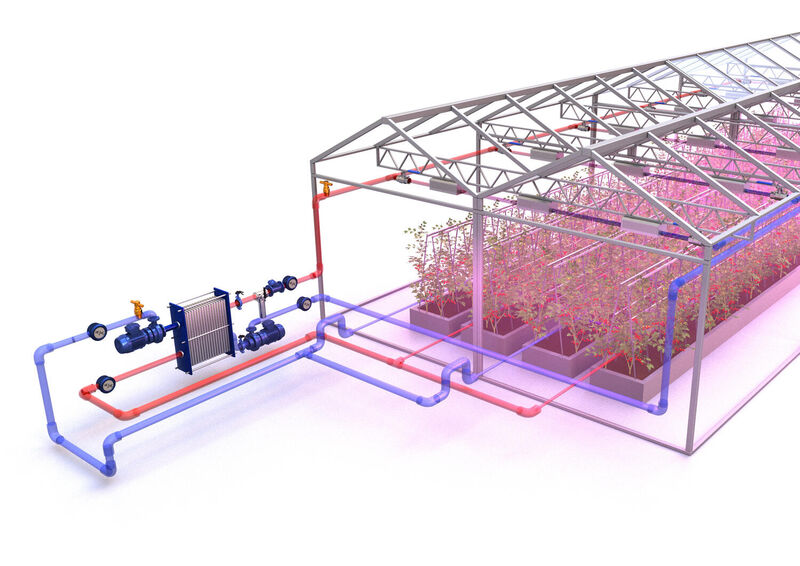

The water cooling system usually consists of 2 water circuits separated by a heat exchanger. The first circuit provides a constant flow of water between the heat exchanger and the fixtures. Cool water is pumped to the lamps, where the water extracts the excess heat from the lamps. The hot water flows back to the heat exchanger, where it is cooled by the second circuit (separated from the first).

The water from the second circuit can come from a basin, but can also be actively cooled by a dry-air cooler, an HVAC or a silo. There are various options and together with the installer it is determined which solution best suits the specific business operations of the grower.

This video explains the water cooling technique:

Reuse of recovered heat

The heat gained from the fixtures has a maximum temperature of 45°C and can be reused. There are several options to directly benefit the crop; the heat can be reused directly under the grow bench, in grow pipes between the crop (image) or in hoses below the crop. In addition, growers often use the gained heat to heat the spray water for the plants or the water in hydroponic ponds. Another option is to store the extracted heat undergrounds, to heat the greenhouse or other business premises in the winter. The full energy of the lamp is used in this way.

Discover all water cooling solutions

Advantages of active water cooling

Thanks to the active water cooling, the design of the fixtures is very compact and in combination with the high light output, less fixtures are needed in the greenhouse. This results in minimal shade and maximum use of natural sunlight. The climate in the greenhouse or cultivation facility remains stable, allowing longer light exposure to benefit the crop. Considerable savings can be made on the purchase and energy costs of cooling/HVAC.

All advantages of water coolingImportance of water cooling

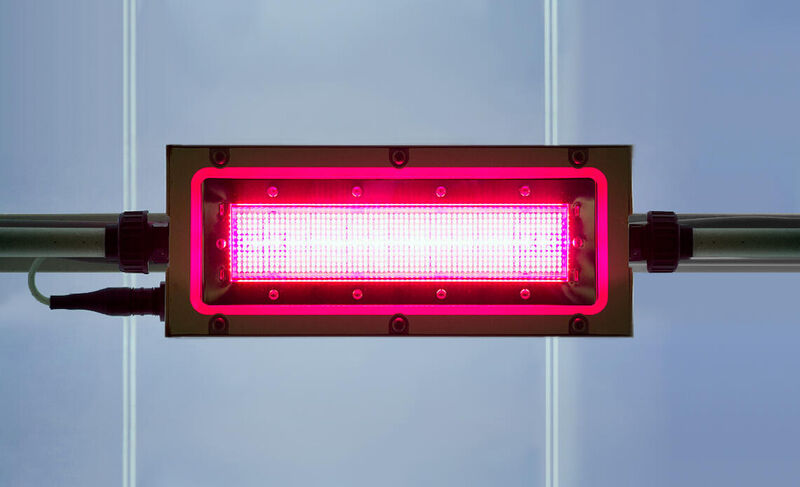

Oreon's LED fixtures are water cooled. Water cooling is by far the most efficient way to cool LED fixtures, as evidenced by the low junction temperature (the hottest point of an LED) of the LEDs (approx. 45°C). The driver, which provides the power supply, also remains continuously cooled by the water. It is important to properly cool LED fixtures: they last longer and deliver a higher and more constant light output at a low temperature. Also, the lower operating temperature is important for the other components in a fixture.

More about our fixtures

Sustainable Solution

Sustainable Solution

Reusing the extracted heat from the fixtures lamps by the water cooling technique is an extremely sustainable solution: by reusing the heat, a grower can make optimal use of the energy consumption of the LED fixtures and at the same time saves on cooling costs, resulting in maximum energy savings.